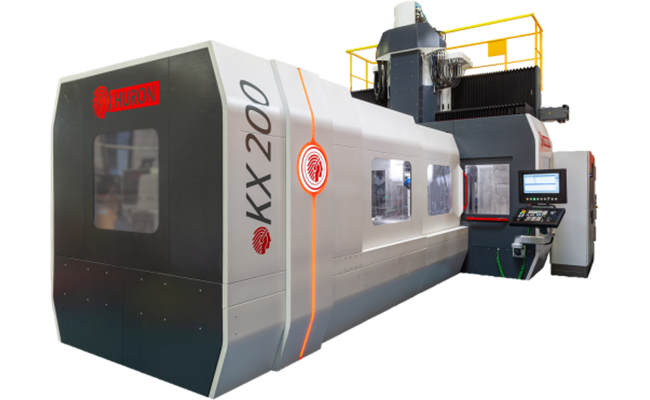

The KX Large Series offers a wide selection of machines for continuous five-axis/five-side machining of complex parts.

The fixed-portal architecture and machine design ensure maximum rigidity for extremely precise machining in a variety of difficult materials.

Its large work area, capable of supporting up to 20 tonnes in weight and accomodating processable volumes up to 4.080 x 2.180 x 1.550 mm, is suited to machining large parts for general mechanical and precision engineering, 3D shapes, and the aeronautical and energy sectors.

Customer reguirements are comfortably met by the modularity of design, the choice of variants, and equipment.

Key Features

- Machine with palletizing function for increased productivity

- Volumetric precision for making moulds and complex parts

- Wide clearance between the columns to exploit the work volume fully

- Spindle offering optimum performance for roughing and finishing

- Spindle suited to high chip rates

- Structural design guaranteeing long mechanical life

- High degree of precision due to direct measurement on the linear and rotary axes

| KX 200 | ||

| Linear axes | ||

| X axis | mm | 3.300 |

| Y axis | mm | 2.300 |

| Z axis | mm | 1.000 |

| Rapid feedrate | m/min | X : 25 Y / Z : 40 |

| Rotating axes on head | ||

| Type of head | Forked head | |

| Rotating axes | B - Swivelling axis : +/- 105° C - Rotating axis : +/- 190° | |

| Rotating speed | rpm | B, C : 30 |

| Torque : motor / clamping | Nm | 7.000 |

| Table | ||

| Structure | Fixed table | |

| Table size | mm | 3.500 x 1.250 |

| Admission load on table | kg | 12.000 |

| Spindle | ||

| Rotating speed | rpm | 18.000 |

| Tool taper | HSK 63-A | |

| Power | kW | 30 |

| Torque | Nm | 240 |

| Characteristic speed | rpm | 1.200 |

| Automatic tool changer | ||

| No. of housings | 40 | |

| Max. tool diameter | mm | 100 / 190 |

| Max. tool weight | kg | 8 |

| Max. tool length | mm | 300 |

| Accuracy (as per VDI / DGQ 3441) | ||

| Uncertainty (P) | X / Y / Z : 0,007 mm B, C : 10 sec | |

| Repeatability (Ps medium) | X / Y / Z : 0,004 mm B, C : 5 sec | |

| Over-all measurements (Doors opened + conveyor) | ||

| Width | mm | 8.000 |

| Depth | mm | 10.690 |

| Height | mm | 5.410 |

| Weight of the machine | mm | 41.000 |

* Depend upon clamping arrangement, Tooling & Job

# Refer machine detailed layout