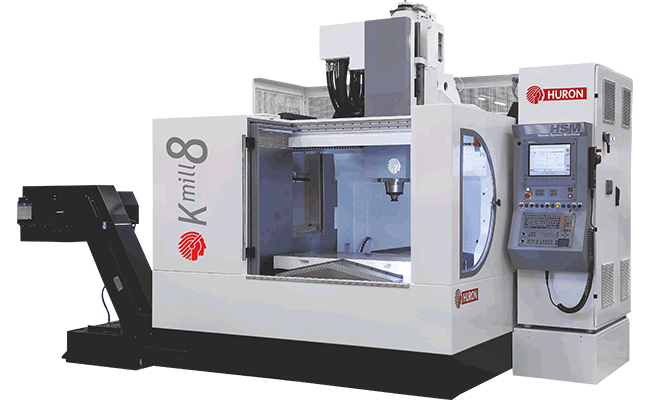

Kmill

KX, a timeless name given to the first portal-structured machine and one that still features in the HRUON product range. It incarnates the most efficien concept for machining complex parts along three axes, from roughing to finishing.

This series of machines combines dynamic action and precision for top quality surface finishes, espacially for 3D shapes for moulds, forgings and tooling.

Key Features

- Ribbed cast iron structure offering high mechanical performance for greater rigidity

- Excellent absorption of the vibrations generated by the tough cutting conditions

- Floor anchoring to maintain geometric stability and precision over time

| Kmill 8 | ||

| Linear axes | ||

| X axis | mm | 700 |

| Y axis | mm | 600 |

| Z axis | mm | 500 |

| Feedrates | m/min | X / Y / Z : 40 |

| Table | ||

| Table size | mm | 800 x 600 |

| Admissible load | kg | 500 |

| Spindle | ||

| Rotating speed | rpm | 15.000 |

| Tool taper | ISO 40 | |

| Power | kW | 23,6 |

| Torque | Nm | 110 |

| Characteristic speed | rpm | 2.680 |

| Tool magazine | ||

| Number of housings | 30 | |

| Max. diameter of tool (contiguous / not contiguous) | mm | 80 / 120 |

| Max. weight of tool | kg | 7 |

| Max. length of tool | mm | 250 |

| Accuracy (according to VDI / DGQ 3441) | ||

| Positioning uncertainty (P) | mm | X / Y / Z : 0,010 |

| Repeatability (PS medium) | mm | X / Y / Z : 0,005 |

| Over-all measurements (Doors opened + conveyor) | ||

| Width | mm | 5.240 |

| Depth | mm | 3.030 |

| Height | mm | 3.060 |

| Weight of the machine | kg | 7.000 |

* Depend upon clamping arrangement, Tooling & Job

# Refer machine detailed layout